Products Category

Contact Us

Tel: 86-532-86850280

E-mail: steven@yaosenmarine.com

Add: NO.8~18 XITAI INDUSTRIAL PARK,QINGDAO,CHINA

Skype: S.L.BLUESEA

QQ:

672098863

Products > Power station,Industrial boiler centrifugal fan > > T6-31,T7-16,T9-28,T9-19 High pressure centrifugal Fan

|

Product name : T6-31,T7-16,T9-28,T9-19 High pressure centrifugal Fan

|

| Details: |

T6-31 T7-16 T9-28 T9-19 High pressure centrifugal Fan

1. T6-31T7-16T9-28T9-19 high pressure centrifugal fan is suitable for fluidized bed boiler primary fan, secondary fan, high pressure head fan and dust removing fan, etc. The maximum temperature can not exceed 250 ℃. This series fan can also be used in other projects.

2, form

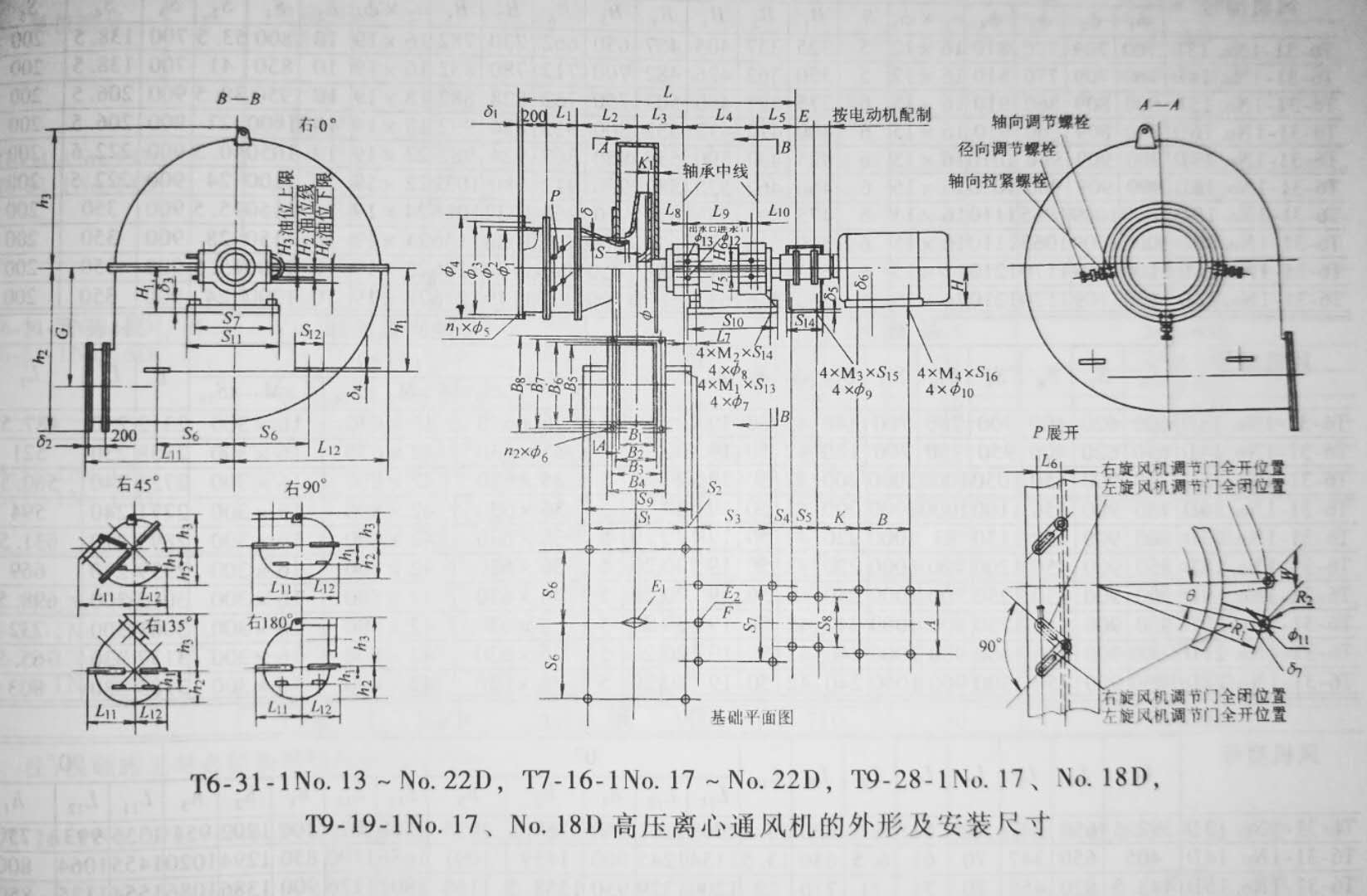

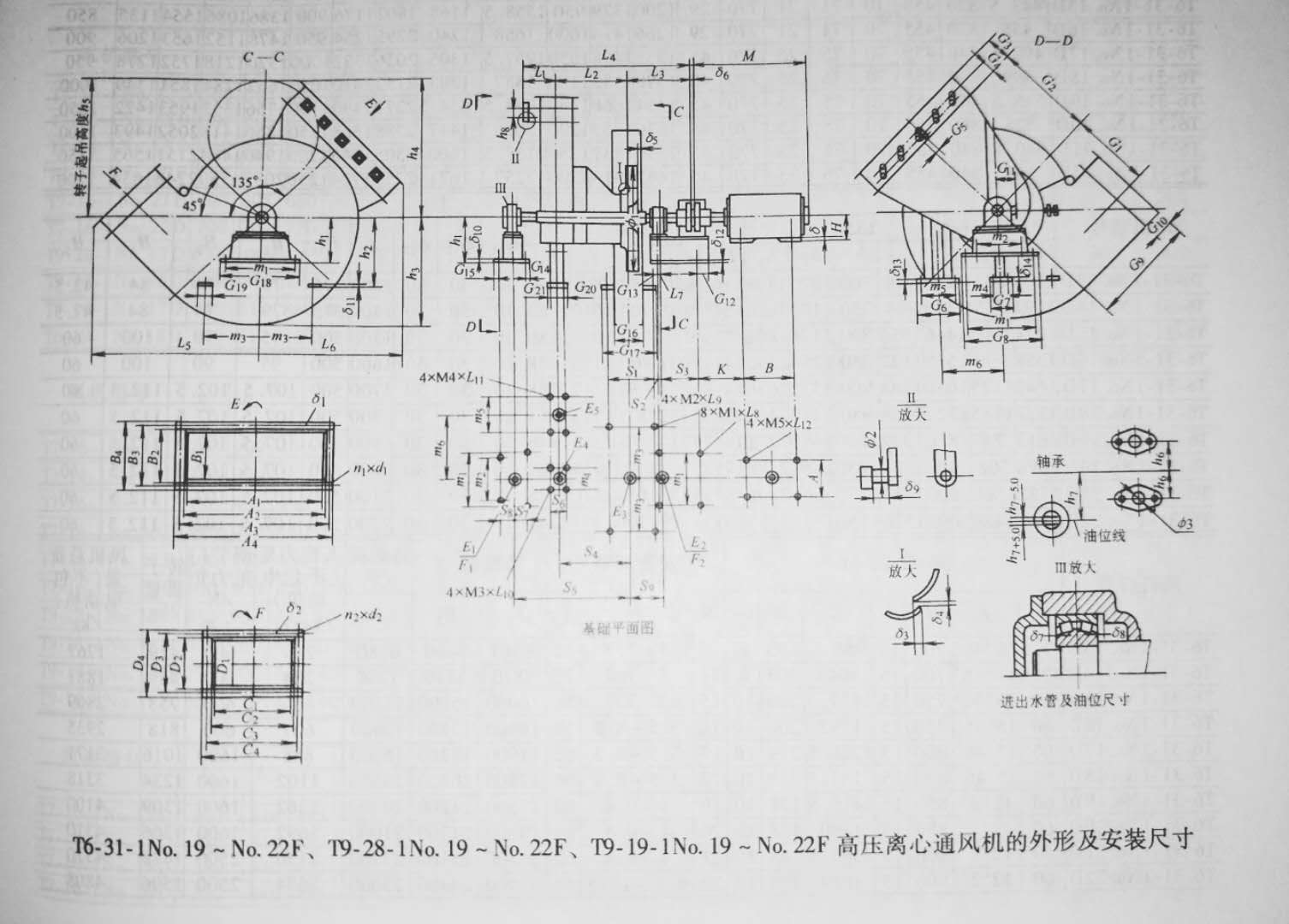

1) the fan is divided into D type, that is, cantilever type, single intake structure, and F type, which is double supporting, single inlet structure, and the two types are 32 machine numbers for selection.

2) each kind of fan can be made into two forms: left rotation or right rotation. From one end of the motor, the impeller rotating clockwise is called right rotating fan, which is expressed as "right". If the impeller rotates counterclockwise, it is called left rotating fan. As "left".

3D type fan is expressed as the inlet of the intake box and the outlet angle of the casing by the angle of the air outlet of the housing.

4) the fan drive mode, the motor in fan connection adopt elastic coupling and diaphragm coupling direct coupling drive.

5) Product full name lift, E. g.: t 6-31 1 / 18D 45 °right.

T6-31-1 / 20F, left 45 °/ 135 °.

The total pressure coefficient of T is the maximum efficiency point of fan No. 6. The whole pressure coefficient is 10 times. 31 is the specific rotation number and 1 is the first design. The impeller diameters are 1800mm and 2000mm respectively.

3, characteristics

1) the performance of the fan is high pressure head, and the middle flow rate is especially suitable for the operating condition of the 35 ~ 410t/h fluidized bed boiler.

2) the operation reliability of the unit is high, the double supporting structure of 19-22F is added on the basis of the cantilever structure of pulverized coal fan to 1500 r / min and the impeller diameter of 2.2 m, which is more reliable.

3) wide range of high-efficiency working conditions, fan machine number is dense, easy to select high-efficiency operating point.

4) adopting the patented technology of "with adjustable inlet". When the fan is installed, the inlet and impeller can be adjusted to the ideal clearance; if there is friction in the operation of the fan, the inlet can be adjusted to the appropriate position; and the inlet and impeller can be removed from the fan when the fan is overhauled, The rotor can be carried out vertically.

5) the patent technology of "oblique cone type air inlet" is adopted in the blower fan with double support, which eliminates the strong cochlear flow area in front of the inlet and ensures the air intake stability.

6) the axial adjusting door and radial adjusting gate are adopted, which have no "dead point" in the adjustment process, so the adjustment is flexible, labor-saving, safe and reliable, and ensures the actuating mechanism can not be loaded.

7) Oil leakage proof bearing box. SKF imported bearing is selected, and the oil from high speed rotating bearing belt is dumped by lap type oil jetting ring to return oil pool of inner wall of bearing box: semicircle type aluminum oil seal, except for convenient maintenance and prevention of friction accident, It can increase the resistance along the axial direction and cut part of the thin oil back into the oil tank; the lateral pressure plate is to block a small amount of thin oil; the upper part of the bearing box is equipped with air plugs to reduce the micro-positive pressure in the bearing box to ensure no oil leakage and good dust-proof performance.

8) the fan is complete. It includes adjusting door, coupling cover, inlet and outlet flange, flexible connection of inlet and outlet, whole set of anchor bolt, thermometer and so on. It can also include complete set of actuators, mufflers and so on.

9) relevant parameters are provided, including the weight of main parts, static and dynamic load, rotor flywheel torque, resistance moment curve of fan starting process, resistance moment of adjusting door and shape size, etc.

10) key measures for ensuring the quality of products

According to national standard and industry standard design naming fan model.

Fan performance is obtained from similar conversion according to fan model test, and the data is reliable.

Nondestructive testing is performed according to standard when the diameter of the fan impeller is greater than 2m or the speed of the fan is over 100m/s.

When the speed of impeller is high, such as Φ 1700mm impeller, use reinforced blade and cover plate.

The inlet and outlet of the fan are equipped with torsional joint belt to prevent the interference of the deformation stress between the pipe and the fan.

4, performance and selection

1) the performance of the fan is expressed by its flow rate, total pressure, spindle speed, shaft power and efficiency.

The performance of the blower is calculated according to the air medium of t _ 0 ~ (20 ℃), atmospheric pressure (Pa _ (0)) 101325 Pa, gas density ρ _ (0) ~ (2) ~ (2) kg / m ~ (3) and gas density ρ _ (0) ~ (2) kg / m ~ (3).

The performance in the selection curve and performance table refers to the performance of the regulating blade at full open zero degree. The performance table shall prevail when ordering. The deviation of the total pressure value of the fan performance test is not more than ±5 percent of the design full pressure value.

If the operating conditions of the fan are not in accordance with the above mentioned, the performance shall be converted according to the relevant formula.

The selection of motor power shall generally not be less than the required power value.

2) the performance table is converted according to the model test data.

3 ) When the flow is too much or insufficient , the processing is as follows :

When using, the phenomenon of excessive or insufficient flow often occurs, and there are many reasons for this phenomenon, if it occurs in the process of use when the flow rate is large and small, The main reason is that the resistance in the pipe network is large or small. If the resistance in the pipe network decreases gradually over a long period of time, or decreases suddenly in a short period of time, it is mainly due to the blockage of the pipe network.

After the new installation of the fan, the main reasons for the excessive or insufficient flow rate during the formal operation are as follows:

There is too much difference between the actual and calculated values of the pipe network resistance.

From the general pipe network characteristic equation: 1: 1 KQ 2, the K resistance coefficient is obtained.

If the actual value K is less than the calculated value K, the flow rate increases, and if the actual value K is greater than the calculated value K, the flow rate decreases.

The total pressure deviation Δ p of the fan itself is not taken into account in the selection. When the actual total pressure of the fan is positive deviation, the flow rate increases, and the flow rate decreases when the fan is negative deviation.

One of the following methods may be eliminated when the fan is newly installed , or when the flow is too large or too small during use :

Use the opening and closing degree of the adjusting door to adjust the flow rate.

Use the speed of the fan to adjust the flow.

Use the new high or low pressure fan to increase or decrease the flow.

Change the resistance coefficient K and change the discharge.

When the adjusting door is completely open, the flow rate is still too small. At this time, the resistance coefficient of the pipe network can be reduced to increase the flow rate, and the fan with higher fan speed and exchange pressure can also be increased, provided that the speed of the fan is not greater than the maximum speed in the performance table.   Please contact us and get detailed Technical parameters and Drawings. We could Design and Produce the Marine fan,Industrial Fan,and Other Ventilation Equipment according to your detailed requirement ! |

| Related Products : |

Marine Axial Flow Fan

Marine Axial Flow Fan