Products Category

Contact Us

Tel: 86-532-86850280

E-mail: steven@yaosenmarine.com

Add: NO.8~18 XITAI INDUSTRIAL PARK,QINGDAO,CHINA

Skype: S.L.BLUESEA

QQ:

672098863

Products > Power station,Industrial boiler centrifugal fan > > G/Y4-73 Industrial boiler use high temperature centrifugal blower

|

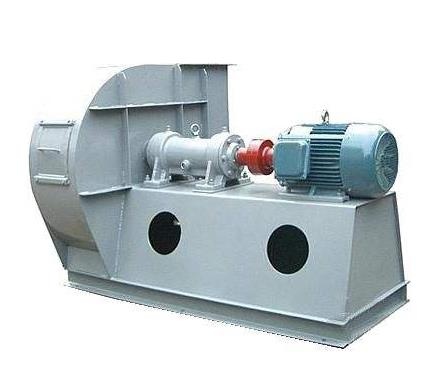

Product name : G/Y4-73 Industrial boiler use high temperature centrifugal blower

|

| Details: |

473 Series Industrial Blower fan for boiler use

G/Y4-73 Series Industrial Centrifugal Blower Fan 1. Applications

Mainly used in blower and draught fan system of steam boiler,coal fired boiler,waste heat recovery boiler,and various boilers.

2. Product Characteristics

•Driving Mode: Coupling;

•28 arc-designed blades enables the blower operates with high air pressure and large air volume;

•Abration resistant and low noise;

•Multi-purpose designed and high efficiency;

•Customized design and production

3. Production Parts:

•Standard Configuration:

case, impeller, air inlet, motor, system integral pedestal, main shaft, driving system (bearing house, bearing), coupling

•Optional Product Parts:

(1) soft connection, air control valve, silencer, air filter, damper, electric actuator, motor with variable frequency and speed regulation, frequency converter, soft starter for motor.

(2) Impellers of high temperature resistant alloyed steel are optional for the high temperature boilers.

4.The following points should be paid attention to durning the process of installation:

(1) Smear some graese or machine oil on some junction surfaces in order to prevent rusting, and reduce the

difficulties when moved.

(2) When fixing the scew bolts on the junction surfaces,if there are Positioning pins,fix the Positioning pins first

then the screw blots.

(3) Check the inside of the chasssis and other cases to make sure that no tools and other substances are left in it .

5.The requirements of insallation:

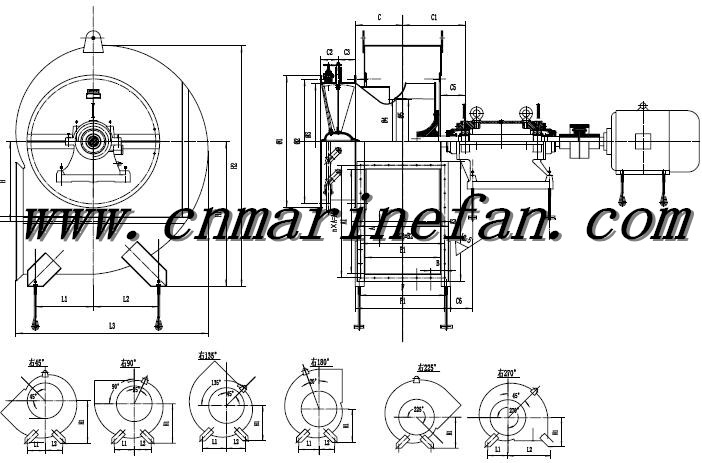

(1) Install the fan according to the positiong and size indicated in the fifure.Pay a special attention to the dimension

of the gap between the inlet port and centrifugal impeller to get high efficiency.

(2) Make sure that the spidle is in horizontal position.Measure the concentricity of the spindle and motor axle.

(3) When to install the adjusting valve,do not put it reversely .Keep the inlet direction in step with the running

direction of centrifugal impellers.

(4) After the installion,move the rotor with hand or a lvver to check whether the motor is too tight or bump the

fixed part.

(5) Do not put any weight on the fan chasssis when to install the pipes and outlet of the fan.

(6) Examine thoroughtly to see whether it meets the requirements after installed,then carry on the testing.

6.Outline dimensions: |

| Related Products : |

Marine Axial Flow Fan

Marine Axial Flow Fan